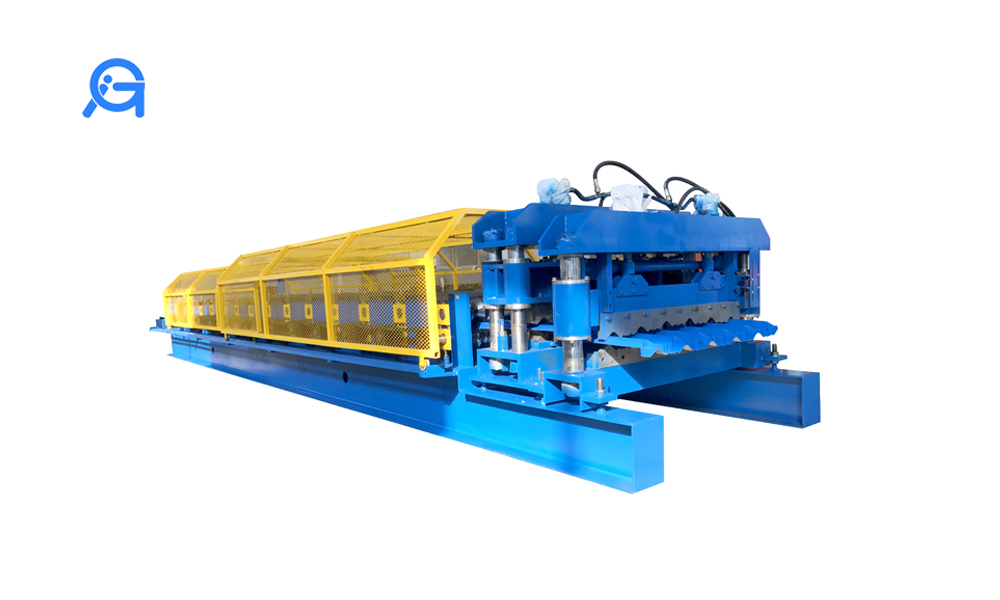

Glazed tile roll forming machine

The glazed tile roll forming machine has a high level of design and manufacturing in the competition of domestic suppliers.

Especially in manufacturing, assembly and material use.The company has advanced production equipment and a professional team with more than 20 years of design experience develops and manufactures roll forming machine. With high efficiency, high flexibility, good performance, low production cost,So the glazed tile roll forming machine is a good choice of the cold roll forming machine production.

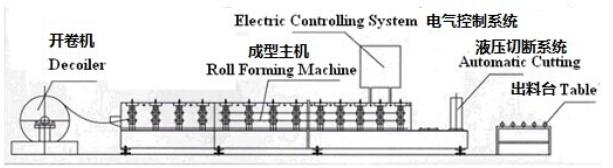

Production Process

Uncoiling→Feeding material into machine→Roll forming machine→Measuring length→Step formed→ Auto cutting →Products receiving

Components of production line

| No. | Name | Unit | Qty |

| 1 | Manual Decoiler | set | 1 |

| 2 | Main forming machine | set | 1 |

| 3 | PLC control system | set | 1 |

| 4 | Hydraulic pump station | set | 1 |

| 5 | Step-formed mechanism | set | 1 |

| 6 | Post cut | set | 1 |

| 7 | Electric motor | set | 1 |

| 8 | Output table | set | 1 |

Production parameters

Processing material: colored steel plate, galvanized plate, or aluminum plate

Material thickness:0.3- 0.8 mm

Material hardness:195 mpa—350 mpa

Material width:1250 mm Wave length:194 mm

Formed width: 970 mm Step height: 30 mm

Step length:150 mm—380 mm(adjustable) Forming speed:4 m/min