One-stop service to global markets with our high quality products and advanced technology

2.Service

Customer service is one of the most important parts of the consumer journey. Our professional team will give you a satisfy buying experience.

Meet customers’ latest requirements with our Research &Development capacity.

4.In Time

We will feedback and delivery to you at the first time.

5.Export

Since our company establish, the accumulated number of export countries exceed 15. And we have established good partnership with many famous company.

General Industry tech Hebei Developing Co., Ltd (GEIT Group) is a professional manufacturer of large and medium-sized machinery and equipment, which can provide best quality machine, good technical support and perfect after-sales service.

Professional sales team, experienced technical engineers and skilled production mechanics are the greatest factor in our success. Mr Cary Xu , the founder of the factory, is a professional sales engineer,who has been engaged in the design and manufacture of cold forming machines since 2006 and has served manufacturers and distributors in more than 100 countries in the world,achieving good fame.

At present, GEIT Group can provide all kinds of cold roll forming machines, including: roofing sheets machine, wall panel machine, C Z purlin machine, light steel gauge machine, metal embossing machine, door/window system forming machine, ceiling system machine, pipe welding machine, slitting and cut to length machines, rack system machines, floor decking machine, and so on. The GEIT Group has passed ISO9001 quality control system certification, European CE safety certification, North American CSA electric certification, and brings the concept of \"time is money, quality is life\" into the mind of every employee .We strictly control quality while improving production efficiency and shortening delivery time.The QC inspection team has always adhered to the principle of \"testing the equipment before leaving the factory and never delivering the problem equipment to the customer\".

With many years of export experience, GEIT Group has fairly well understood the different needs of customers from both developing countries and developed countries,and provides customers with satisfactory design solutions. Nowadays our machine has been exported to more than 90 countries and we have established long-term and stable cooperative relationship with our clients.

WHAT WE DO&List

FAQMore

Routine check and preparation of roller shutter door making machine

Cold roll forming is a kind of material saving, energy saving and high speed metal forming process. Cold roll forming is a multi-pass forming roll equipped in sequence. The coil, strip and other m ... + Read more

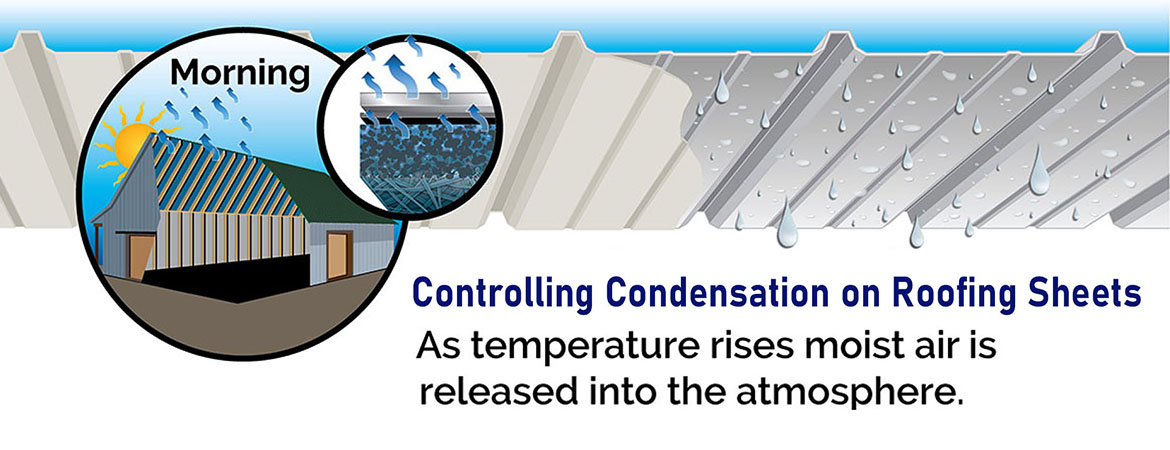

How does roof sheet machine affect the quality of the color steel plate

Many customers are most concerned about the quality of the color steel plate produced when purchasing PPGI sheet metal roofing IBR profile machinery. Because machine processing will directly affec ... + Read more

How to maintain the roof sheet machine in winter

Cold forming machine can face some special challenges in winter, as snowy weather is usually accompanied by lower temperatures and possible adverse weather conditions. GEIT GROUP reminds you to pa ... + Read more

WHAT WE DOMore

Multifunctional direct selling ibr color steel roll forming machine made in China for house roofing tile machine

Trapezoidal tile Roll Forming Machine Main Roll Forming System: Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped. Leng ... + Read more

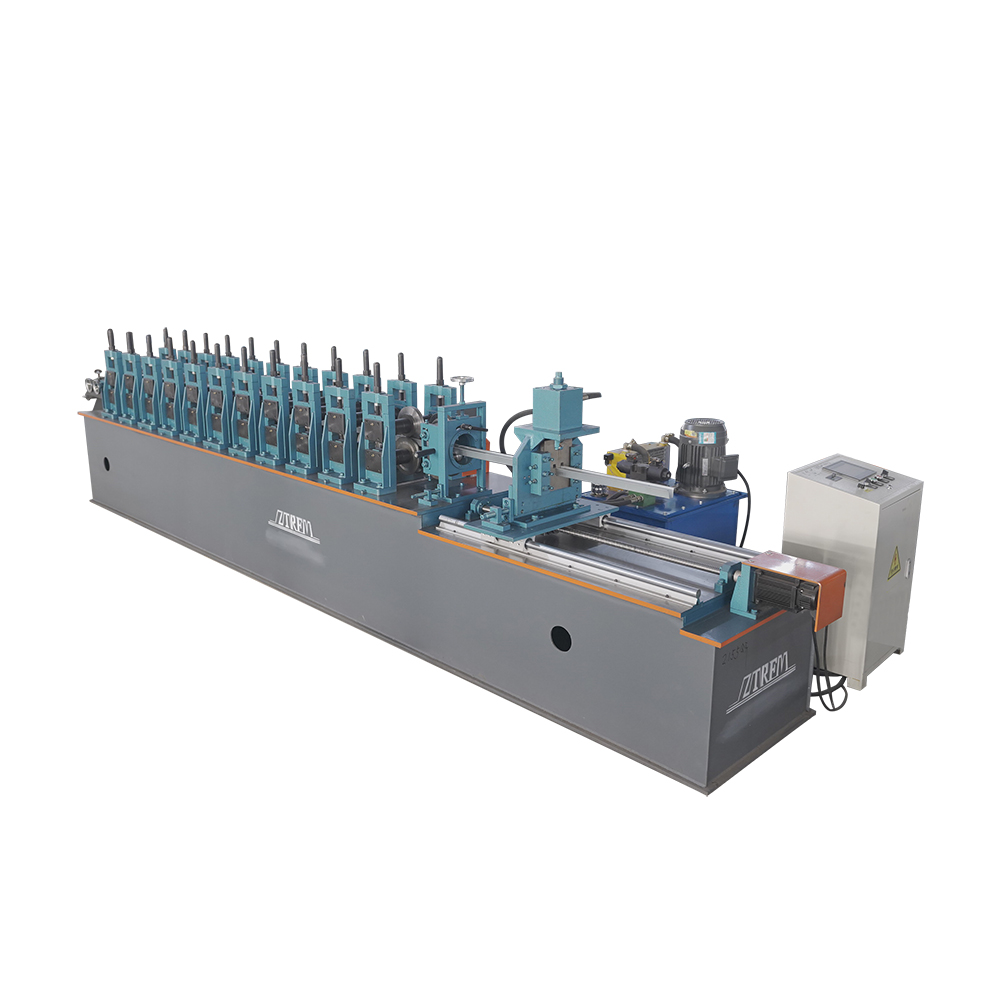

50 75 100 channel ce certificated partition system Light steel keel forming machine

Light keel Roll Forming Machine Main Roll Forming System 1.Length of the main part:about 3000*1000*400 2.Weight of main part:3 tons 3.Voltage:380V/50HZ3Phase (as customer`s request) 4.Roller fixer:guide column 5.Frame:steel plate welded/ Memorial arch frame type 6.Frame thickness:25mm 7.Drive mode:gear 8.Ma ... + Read more

ce certificated light steel keel Roll Forming Machine

Details of light keel roll forming machine 1.Length of the main part:about 3000*1000*400 2.Weight of main part:3 tons 3.Voltage:380V/50HZ3Phase (as customer`s request) 4.Roller fixer:guide column 5.Frame:steel plate welded/ Memorial arch frame type 6.Frame thickness:25mm 7.Drive mode:gear 8.Material of rolle ... + Read more

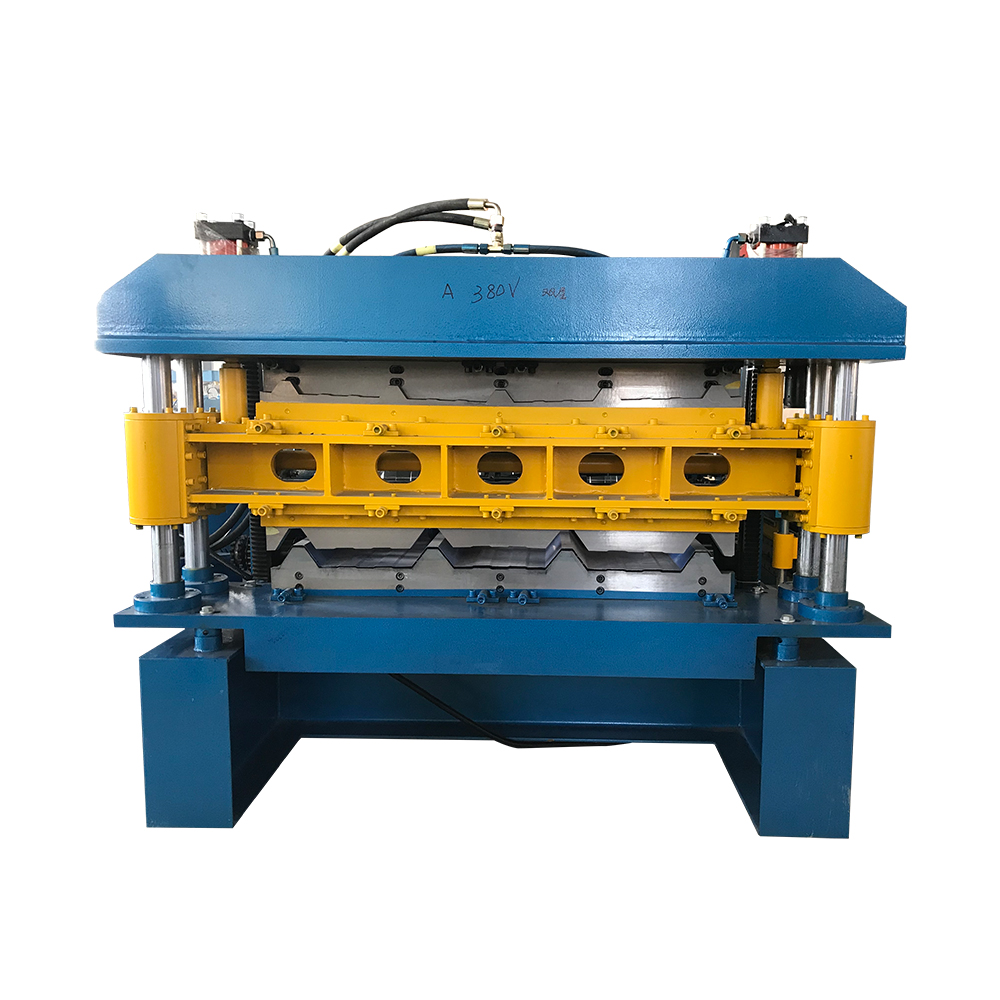

Ibr Pbr Bir Tile Roof Panel Roll Forming Machine

Product Description Trapezoidal tile Roll Forming Machine Main Roll Forming System: Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it i ... + Read more

Decking Floor Roll Forming Machine

Product Description Floor deck Roll Forming Machine Main Roll Forming System: Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being ... + Read more

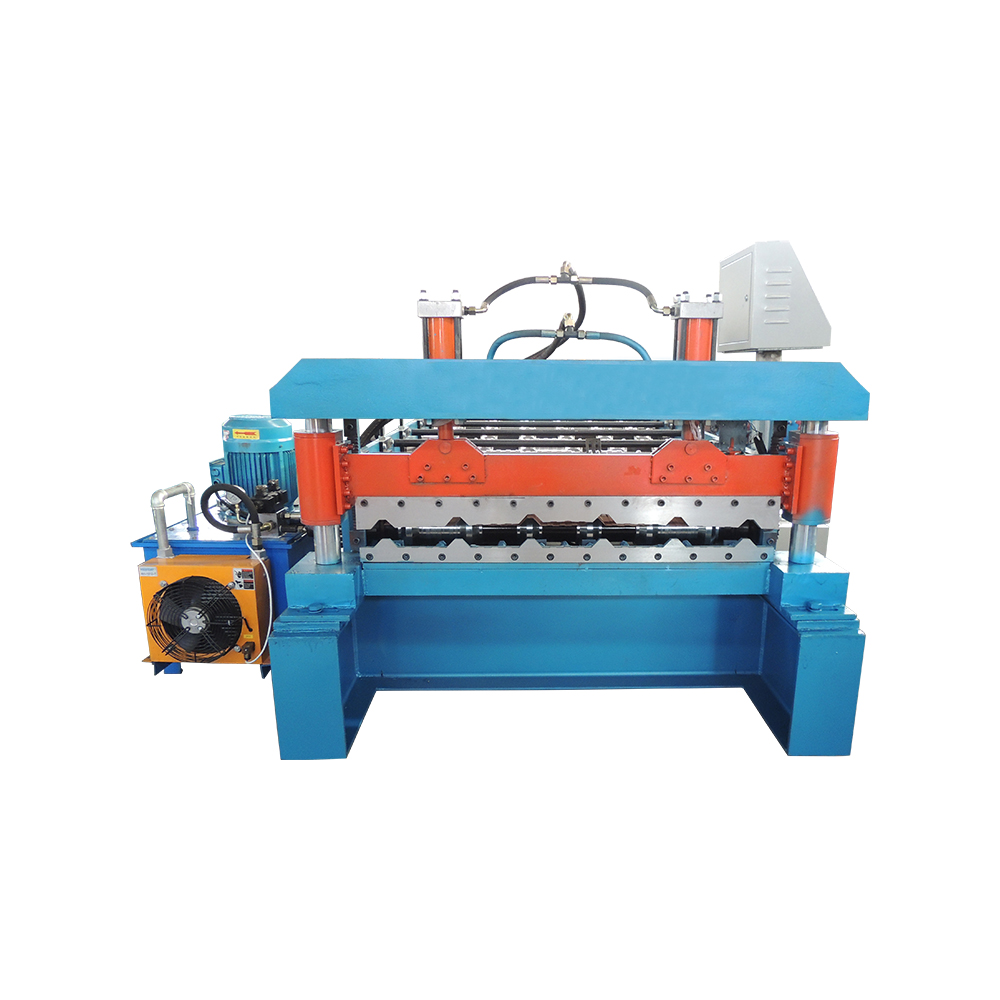

thicker material and color steel double layer roll forming machine

Product description Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped. Length of the main part: about 6500х1450х1500 We ... + Read more

full automatic light keel roll forming machine

Production description 1.Length of the main part:about 3000*1000*400 2.Weight of main part:3 tons 3.Voltage:380V/50HZ3Phase (as customer`s request) 4.Roller fixer:guide column 5.Frame:steel plate welded/ Memorial arch frame type 6.Frame thickness:25mm 7.Drive mode:gear 8.Material of rollers:GCr12MoV 9.Mate ... + Read more

Double layer roll forming machine

Double layer Roll Forming Machine Main Roll Forming System: Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped. Length o ... + Read more